What should be taken into account when arranging the production premises?

Setting up production facilities is an essential part of effective business management and optimization of the production process. Here are some factors to consider when setting up your production space:

Explore and evaluate:

Do detailed research and evaluate possible solutions to ensure that your production space fit-out meets your company's goals and needs.

Ergonomics and worker safety:

Ensure that employees can move freely between workplaces, minimizing unproductive movement and time loss resulting from ill-conceived room layout. Plan the placement of workplaces and equipment in such a way as to ensure employee safety and optimal ergonomics.

Work flow:

Develop an efficient workflow to minimize travel and material handling time. Metal work tables with different types of surfaces, which can be adapted to any work purpose, are very useful for such a purpose. It is important to observe the basic principles of arranging work spaces.

Energy efficiency:

Use energy-efficient equipment and systems to reduce energy consumption, thereby significantly optimizing costs. If possible, use energy-efficient lighting solutions.

Storage and flow control:

Assess the need for storage spaces and organize warehouse space by efficiently equipping them with different metal shelving systems depending on the type of goods and products to be placed in them.

Ensure efficient cargo flow and control to avoid delays in the execution of work, which can cause additional loss to your company.

Adequate room ventilation:

Ensure optimal ventilation and air quality to maintain a healthy work environment.

Flexibility and adaptability:

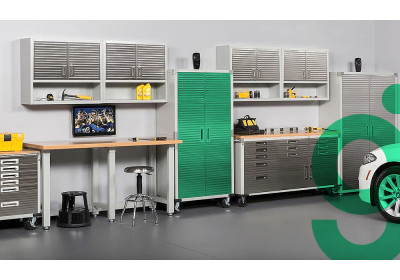

Arrange the room to adapt to changing production volumes and requirements. Use modular and flexible systems of shelves, work tables, cabinets and work surfaces that allow you to easily adapt to changes that may occur as your business develops and expands.

Employee engagement and training:

Ensure that employees are trained and have a good understanding of the production and storage process, as well as the effective use of equipment, warehouse and production room equipment and the technologies implemented.

In general, when setting up production facilities, it is important to take into account efficiency, safety, flexibility and technological development in order to ensure the optimization of the production process and the company's competitiveness.

Mezzanines / Intermediate platforms

Mezzanines / Intermediate platforms Shelves and warehouse equipment

Shelves and warehouse equipment Metal cabinets

Metal cabinets Workbenches, desks and tables

Workbenches, desks and tables PVC strip curtains

PVC strip curtains Storage boxes

Storage boxes Metal containers and waste management equipment

Metal containers and waste management equipment Floor covering for workshops

Floor covering for workshops Safety equipment

Safety equipment Pallets and pallet accessories

Pallets and pallet accessories Storage racks

Storage racks Warehouse and shop trolleys

Warehouse and shop trolleys Cargo trolley

Cargo trolley Electric pallet trucks

Electric pallet trucks Electric stackers

Electric stackers  Forklifts

Forklifts Hydraulic work tables and platforms

Hydraulic work tables and platforms Manual stackers

Manual stackers Pallet trucks

Pallet trucks Reach trucks

Reach trucks Self-lift stackers

Self-lift stackers Semi-electric stackers

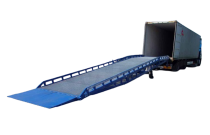

Semi-electric stackers Loading ramps

Loading ramps Forklift equipment

Forklift equipment Dual cabinet industrial tables

Dual cabinet industrial tables Heavy duty workshop tables

Heavy duty workshop tables Laboratory cabinets

Laboratory cabinets Locker cabinets

Locker cabinets Mobile car service cabinets

Mobile car service cabinets Mobile work tables and drawer units

Mobile work tables and drawer units Warehouse trolleys

Warehouse trolleys Workshop tables

Workshop tables Stainless steel benches

Stainless steel benches Stainless steel cabinets

Stainless steel cabinets Stainless steel shelves

Stainless steel shelves Stainless steel sinks

Stainless steel sinks Stainless steel tables

Stainless steel tables Stainless Steel Work Trolleys

Stainless Steel Work Trolleys Changing room benches

Changing room benches Clothing racks

Clothing racks Compartment cabinets

Compartment cabinets Equipment for drying clothes

Equipment for drying clothes Household lockers

Household lockers Shoe cabinets

Shoe cabinets Universal metal shelves

Universal metal shelves Filing cabinets

Filing cabinets Key cupboards

Key cupboards Mailboxes

Mailboxes Medicine cabinets

Medicine cabinets Office storage lockers

Office storage lockers Server cabinets

Server cabinets Built-in safes

Built-in safes Fireproof anti-theft safes

Fireproof anti-theft safes Fireproof safes

Fireproof safes Gun cabinets

Gun cabinets Key cupboards

Key cupboards Office safes

Office safes Laboratory desks

Laboratory desks Laboratory drawer cabinets

Laboratory drawer cabinets Laboratory fume extraction cabinets

Laboratory fume extraction cabinets Medical chairs and couches

Medical chairs and couches Medical mobile cabinets

Medical mobile cabinets Medical mobile carts

Medical mobile carts Medical Screens

Medical Screens Medicine cabinets

Medicine cabinets Sinks and their accessories

Sinks and their accessories Mobile car service accessories

Mobile car service accessories Mobile car service shelves

Mobile car service shelves Cold storage rooms

Cold storage rooms Freezer Rooms

Freezer Rooms Cold panels

Cold panels Cooling Units

Cooling Units Garage furniture sets

Garage furniture sets Metal shelf sets

Metal shelf sets Wardrobe sets

Wardrobe sets Checkout Zones

Checkout Zones Refrigeration Equipment

Refrigeration Equipment Retail shelving systems

Retail shelving systems