Different types of PVC strip curtains and their uses

Why Choose PVC Curtains?

PVC curtains are a versatile and reliable solution used across various industries to improve the functionality and efficiency of spaces. Additionally, PVC curtains are cost-effective and reduce maintenance expenses due to their durability.

Advantages of PVC Curtains:

- Energy saving: Reduces heat loss and helps maintain optimal indoor temperature.

- Sound insulation: Minimizes noise entering or leaving the space.

- Space separation: Perfect for dividing work areas, maintaining hygiene standards, or improving workplace efficiency.

- Protection against external factors: Effectively blocks dust, moisture, and insects.

- Wide application: Suitable for production facilities, warehouses, food storage areas, and more.

- Easy installation: Available with various mounting systems for quick and secure installation.

- Durability: Highly flexible and durable, ensuring a long lifespan even under intensive use.

Main Types of PVC Curtains

Standard PVC Strip Curtains

Suitable for many environments where space needs to be separated or a specific temperature maintained. Made of transparent material, they provide good visibility on both sides while protecting against airflow, dust, and noise. Available in thicknesses ranging from 2 to 4 mm, offering flexibility and durability for warehouses, production areas, and retail spaces.

Frost-Resistant PVC Curtains

Designed for low temperatures, maintaining flexibility even in extreme conditions, ensuring the material does not harden or crack at temperatures as low as -40°C. Ideal for freezers and food storage areas to maintain stable temperatures and minimize energy loss.

Ribbed PVC Curtains

Provide additional protection against scratches and mechanical damage, which is essential in high-traffic areas or places where curtains may experience mechanical impact. Ribbed surfaces extend curtain longevity while retaining flexibility and shape, making them popular in transportation and logistics centers, as well as industrial zones.

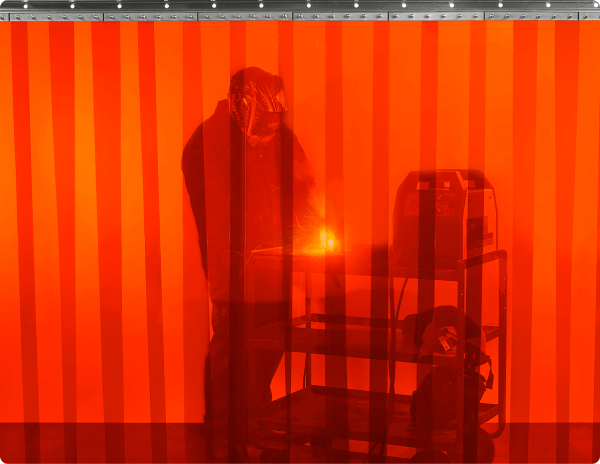

PVC Welding Curtains

Industrial PVC curtains for welding tasks ensure safety in workshops where welding processes are carried out. They effectively block harmful UV and infrared rays while maintaining visibility between work zones. These curtains meet high safety standards and are widely used in manufacturing facilities and workshops where worker protection is a priority.

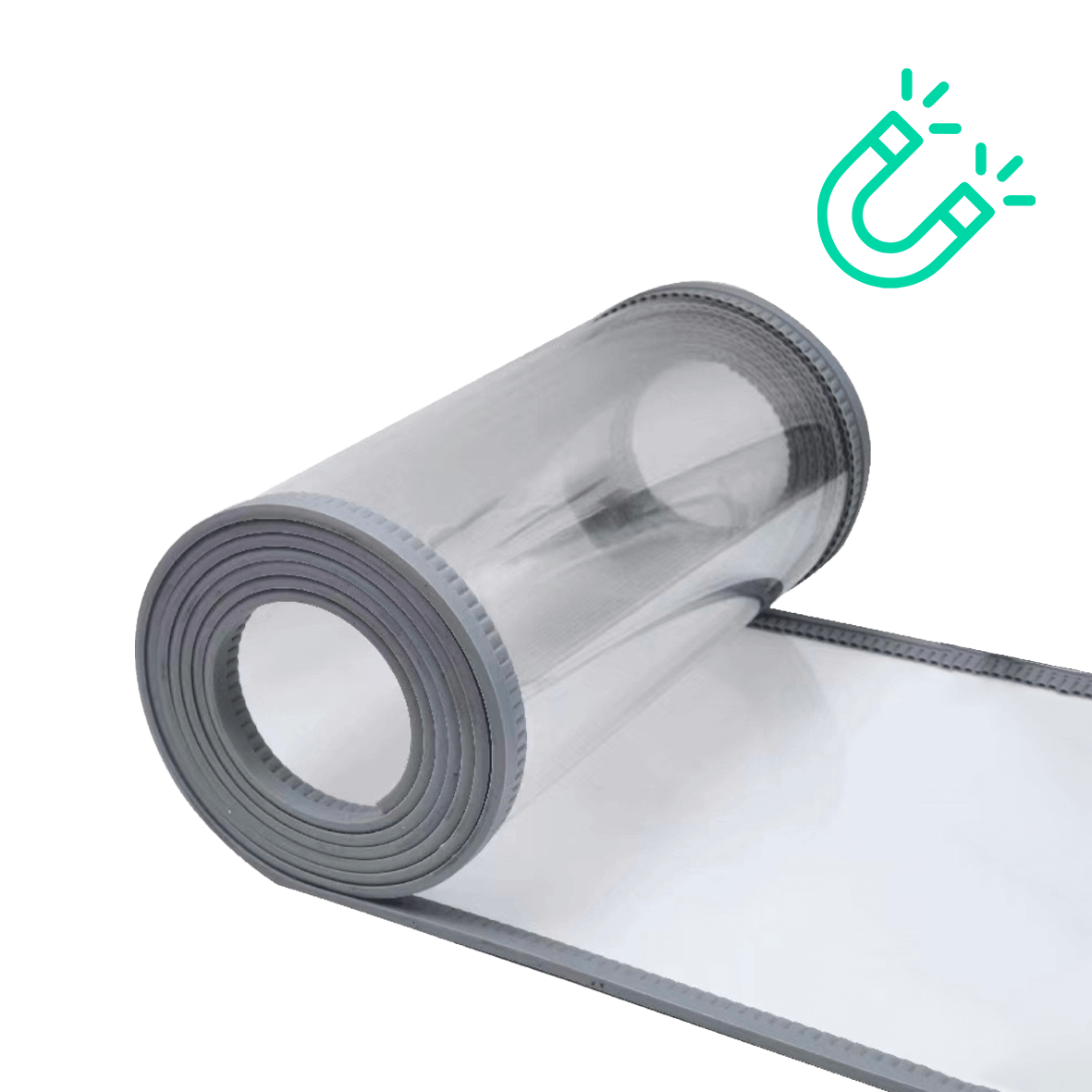

Magnetic PVC Curtains

A modern solution for spaces with high traffic. These curtains automatically close with a magnetic system, ensuring easy passage while maintaining effective temperature control. They effectively prevent dust and insects from entering, making them ideal for food storage areas and similar spaces.

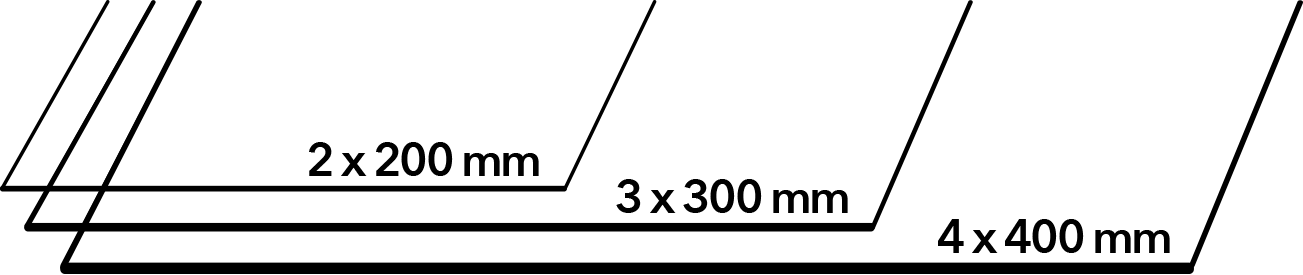

What Width of Strips to Choose?

- 200 mm wide strips: Perfect for low and medium traffic areas like offices, small warehouses, or food storage rooms. They provide good flexibility, easy passage, and sufficient insulation from dust and noise.

- 300 mm wide strips: Suitable for medium to high traffic areas, such as logistics centers, industrial facilities, and production zones. They offer improved durability and better insulation, reducing temperature loss and increasing protection against environmental factors.

- 400 mm wide strips: Used in high-traffic areas and for heavy equipment transportation, such as large warehouses, industrial plants, and logistics centers. These strips offer maximum durability, reduce sound and temperature loss, and withstand heavy mechanical loads and intensive use.

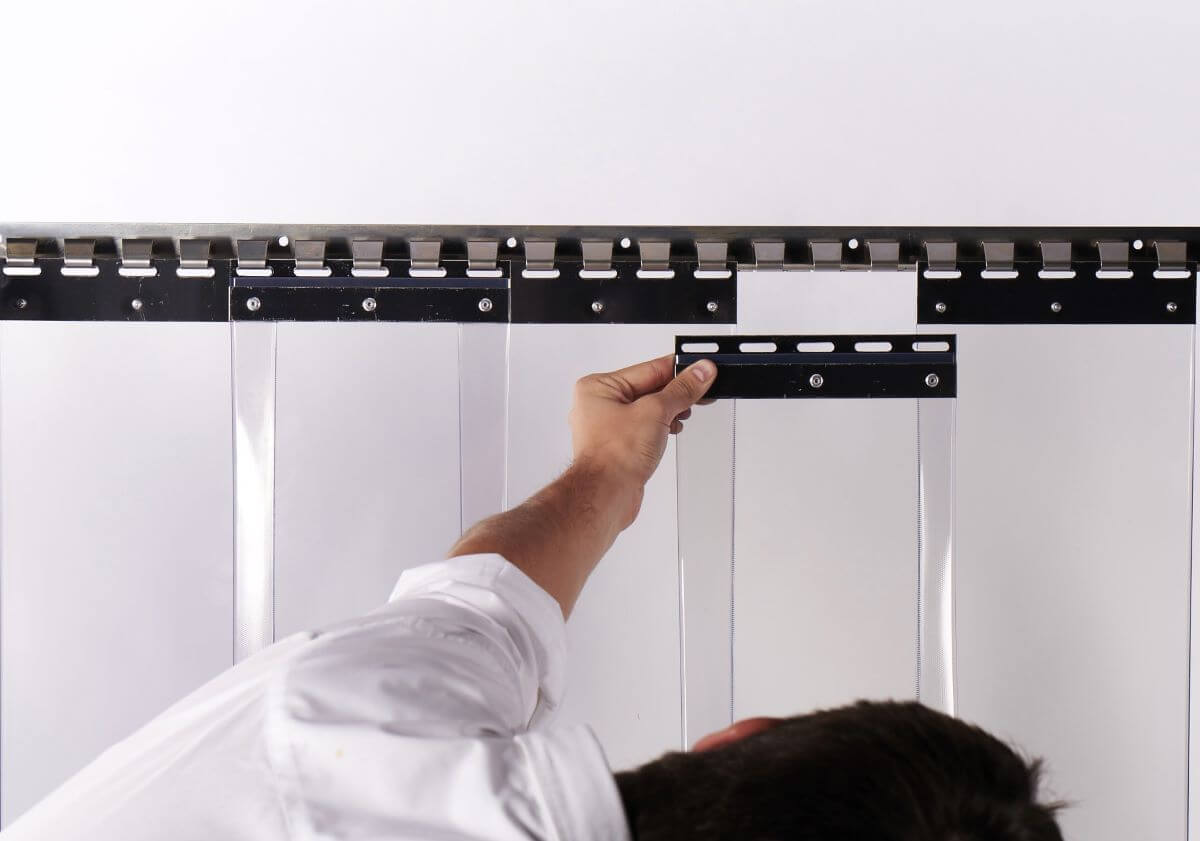

PVC Curtain Installation

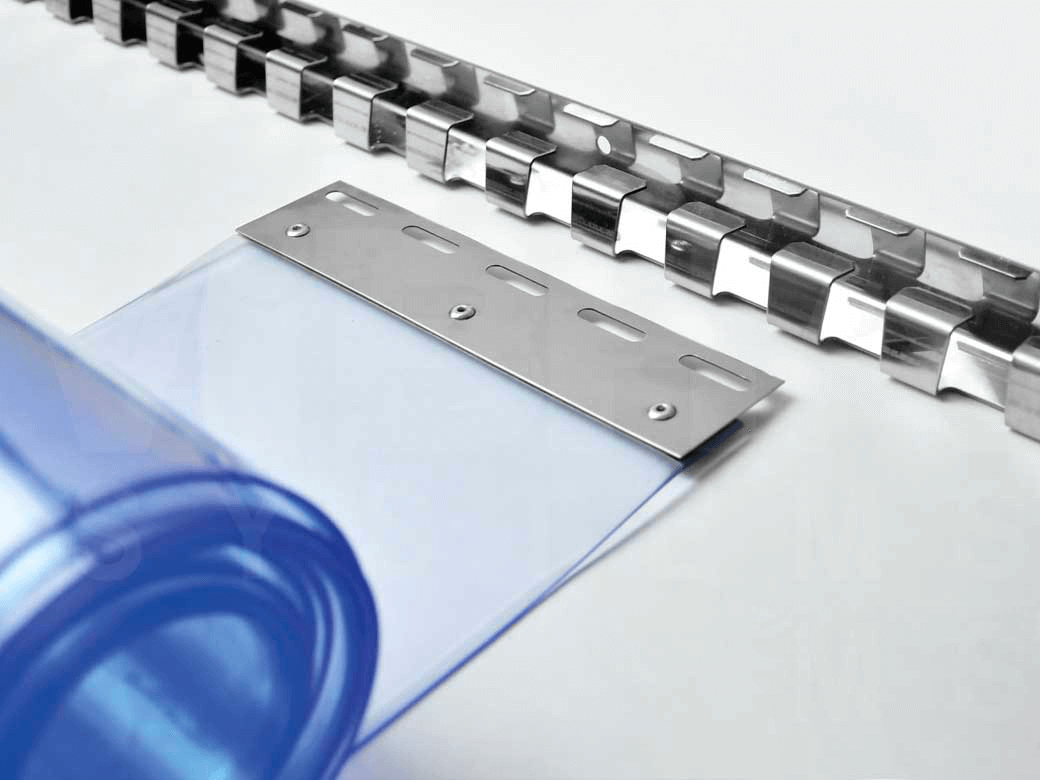

PVC curtain installation is convenient and straightforward thanks to available PVC curtain hangers and brackets:

- Stainless steel mounts: Ideal for wet and aggressive environments such as food production facilities. They provide long-lasting curtain stability and high resistance to corrosion.

- Galvanized steel mounts: A more economical alternative suitable for dry and less aggressive environments. These mounts are resistant to mechanical loads and ensure reliable curtain functionality.

Curtain clamps:

- Stainless steel strip holders: Perfect for aggressive environments, such as wet spaces or areas with high hygiene standards. They are long-lasting and corrosion-resistant.

- Galvanized steel strip holders: Suitable for dry and less aggressive environments. A more cost-effective solution while providing good functionality and durability.

Mezzanines / Intermediate platforms

Mezzanines / Intermediate platforms Shelves and warehouse equipment

Shelves and warehouse equipment Metal cabinets

Metal cabinets Workbenches, desks and tables

Workbenches, desks and tables Metal containers and waste management equipment

Metal containers and waste management equipment Storage boxes

Storage boxes Floor covering for workshops

Floor covering for workshops Safety equipment

Safety equipment Pallets and pallet accessories

Pallets and pallet accessories Storage racks

Storage racks Warehouse and shop trolleys

Warehouse and shop trolleys PVC strip curtains

PVC strip curtains Cargo trolley

Cargo trolley Electric pallet trucks

Electric pallet trucks Electric stackers

Electric stackers  Forklift equipment

Forklift equipment Forklifts

Forklifts Hydraulic work tables and platforms

Hydraulic work tables and platforms Manual stackers

Manual stackers Pallet trucks

Pallet trucks Reach trucks

Reach trucks Self-lift stackers

Self-lift stackers Semi-electric stackers

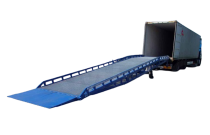

Semi-electric stackers Loading ramps

Loading ramps Dual cabinet industrial tables

Dual cabinet industrial tables Heavy duty workshop tables

Heavy duty workshop tables Laboratory cabinets

Laboratory cabinets Locker cabinets

Locker cabinets Metal shelves

Metal shelves Mobile car service cabinets

Mobile car service cabinets Mobile work tables and drawer units

Mobile work tables and drawer units Warehouse trolleys

Warehouse trolleys Workshop tables

Workshop tables Stainless steel benches

Stainless steel benches Stainless steel cabinets

Stainless steel cabinets Stainless steel shelves

Stainless steel shelves Stainless steel sinks

Stainless steel sinks Stainless steel tables

Stainless steel tables Stainless Steel Work Trolleys

Stainless Steel Work Trolleys Changing room benches

Changing room benches Clothing racks

Clothing racks Compartment cabinets

Compartment cabinets Equipment for drying clothes

Equipment for drying clothes Household lockers

Household lockers Shoe cabinets

Shoe cabinets Universal metal shelves

Universal metal shelves Filing cabinets

Filing cabinets Key cupboards

Key cupboards Mailboxes

Mailboxes Medicine cabinets

Medicine cabinets Office storage lockers

Office storage lockers Server cabinets

Server cabinets Built-in safes

Built-in safes Fireproof anti-theft safes

Fireproof anti-theft safes Fireproof safes

Fireproof safes Gun cabinets

Gun cabinets Key cupboards

Key cupboards Office safes

Office safes Laboratory desks

Laboratory desks Laboratory drawer cabinets

Laboratory drawer cabinets Laboratory fume extraction cabinets

Laboratory fume extraction cabinets Medical chairs and couches

Medical chairs and couches Medical mobile cabinets

Medical mobile cabinets Medical mobile carts

Medical mobile carts Medical Screens

Medical Screens Medicine cabinets

Medicine cabinets Sinks and their accessories

Sinks and their accessories Mobile car service accessories

Mobile car service accessories Mobile car service shelves

Mobile car service shelves Cold storage rooms

Cold storage rooms Freezer Rooms

Freezer Rooms Cold panels

Cold panels Cooling Units

Cooling Units Garage furniture sets

Garage furniture sets Metal shelf sets

Metal shelf sets Wardrobe sets

Wardrobe sets Checkout Zones

Checkout Zones Refrigeration Equipment

Refrigeration Equipment Retail shelving systems

Retail shelving systems